Preparatory actions:

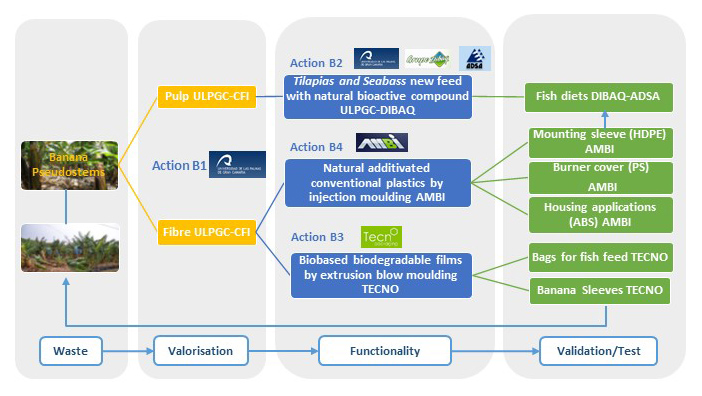

The project will start by developing a protocol for organizing BAQUA product’s testing. These tests will demonstrate the viability of the resulting extracted materials (natural fibres and pulp) in current high volume manufactured products such as films for agricultural and food-related products, improved nutritional fish diets, and plastic parts for household use, enhanced with natural additives.

Implementation and monitoring phases:

Trials will be performed in order to test the innovative features of the products.

· Optimization of waste valorization technologies and characterisation of natural fibres and pulp by ULPGC (equipment, tests and analysis according to AOAC). (Action B1)

· Production of materials (using conventional film blown extrusion by TECNO) and natural additivated plastic parts (using conventional injection machinery by AMBI). (Actions B3 and B4)

· Enhancement of fish feed and diets by means of natural active compounds (meals powders prepared in pilot line in GIA-ULPGC facilities with support of ADSA and DIBAQ). (Action B2).

· Assessment of the environmental footprint of the system (LCA assessment carried out by TECNO).

· Assurance of transferability and replicability (guidelines for BAQUA products implementation in other sectors and with other natural wastes prepared by all partners).

Dissemination actions:

The project’s results will be disseminated at European and international level by means of cooperation with industrial associations. BAQUA counts with the support of Regional Governments (Cabildo de Gran Canaria, Gobiernos de Canarias y de Aragón) and SMES (see LOIs) that will be essential for local dissemination campaigns, throughout local awareness events, technical seminars, open day visits and networking with other LIFE projects.

Project Management:

The Project Coordinator (Mario Monzón) will be full time devoted to management activities and will count with the participation of all partners in different duties. Project evaluation and external auditing will also form part of this action. Finally, the After-Life plan will be made and implemented over 3 years after the project closure with consortium’s own resources.