1. Demonstration of a new circular economic viability:

· Optimisation of green pilot plant for extracting banana fibres which could provide natural fibres (1,000 kg/year) and pulp (10,000 kg/year) with final requirements defined by their users.

· New 100% biobased and biodegradable material for film blown extrusion validated in 2 film plastic products : banana sleeve with UV protection and bags for fish feed conservation and transport.

· New material with 0% of synthetic additives for 3 types of small-medium size plastic parts with conventional functionalities but enhanced with natural rather than synthetic additives: a) mounting sleeve, b) burner cover and c) housing applications.

2. Reduction of at least 30% CO2 and 100% N2O emissions:

· New PLA (polylactic acid) film plastic products produced during the project will achieved approximately a reduction of a 50% according to one of the most important PLA manufacturers.

· New conventional plastic parts with 20% of natural reinforcement instead of synthetic will reduce CO2 emissions between 30 and 60% depending on the type of reinforcement.

· New agricultural practices will eliminate the banana crop wastes abandoned in the soils, reaching at project scale a 100% reduction of N2O emissions.

3. Improvement of fish feed quality by:

· Testing 7 different fish feed diets that will boost fish growth and enhance aquafeed organoleptic properties and fish quality for human consumption.

· Substitution of synthetic antioxidants in fish feed.

· Provide flexibility in the availability of raw materials for fish feed.

4. Report on the project impact on the environmental problems identified and on the socioeconomic conditions:

The project will provide a support document for the Canary Islands Government in order to co-finance the industrialisation of the extraction plant to provide around 2,000 ton/year of natural fibres and 20,000 t/year of pulp.

5. Contact with an audience of at least 1,000 local consumers in the community and 10,000 website visitors:

Awareness-raising on sustainable agricultural practices and agro-waste revalorization.

6. Analysis of replicability and transferability:

At least to two other natural sources (vegetable crops) and three regions (Spain, Slovenia and Sweden). Regarding end products, with knowledge gathered it will be studied the potential to apply extracted pulp and fibres to other plastic products and cosmetics, food or pharma sectors.

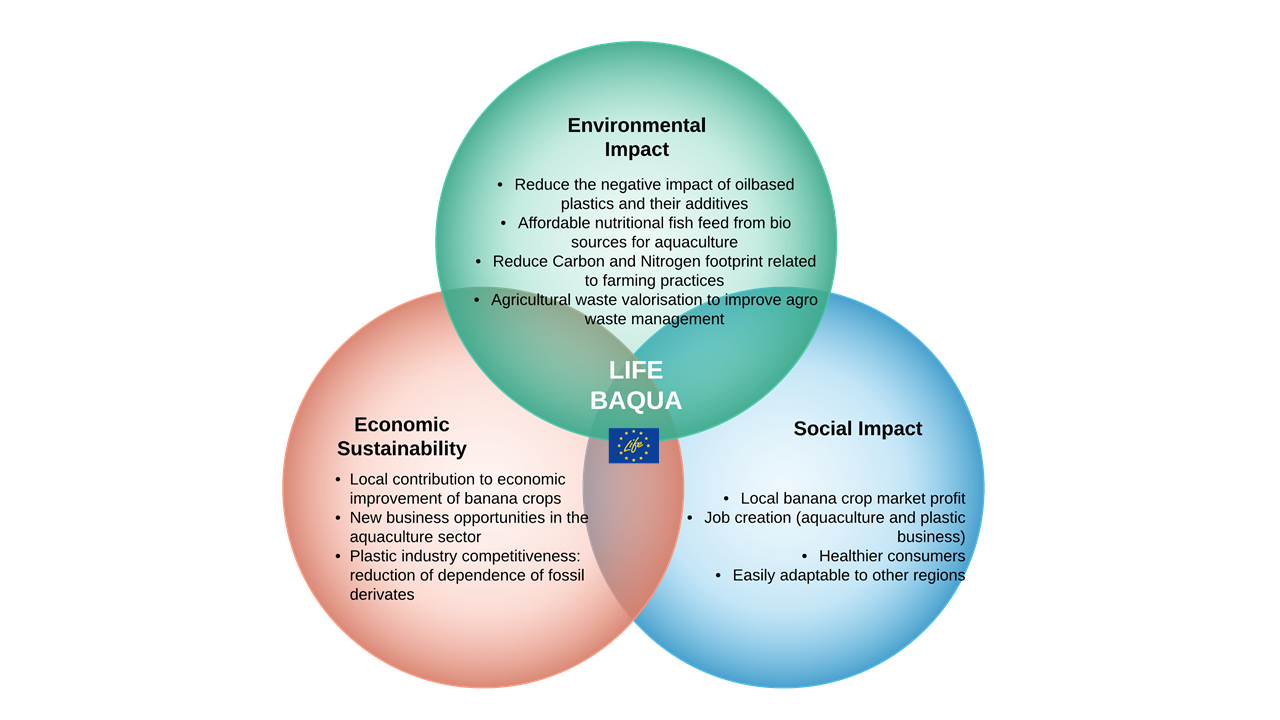

BAQUA has the potential to exert a positive impact on environment, on society (mainly local communities) and on the economy (bringing sustainable new business models) in the European Union.